UNSW Engineering / Industry Partnership: Smart De-Construction – reducing industry emissions.

There is nothing conventional or simple about modern demolition work, which requires significant engineering nous and experience to bring structures down safely and on time, fully cognisant of project efficiency, client budgets and, crucially, environmental responsibility.

There is nothing conventional or simple about modern demolition work, which requires significant engineering nous and experience to bring structures down safely and on time, fully cognisant of project efficiency, client budgets and, crucially, environmental responsibility.

Bringing a building down is like a massive 3D puzzle, where the team must be able to see the process from every angle. ‘We have to be very systematic with every project,’ says demolition expert Frank Lombardi, ‘you need to be thinking 20 steps ahead all the time.’ De-construction is of necessity smart construction.

Lombardi is Director of DECC, a privately owned and operated Australian company founded in 2007, which specialises in commercial and industrial demolition, environmental services, civil contracting, and remediation and hazmat removal.

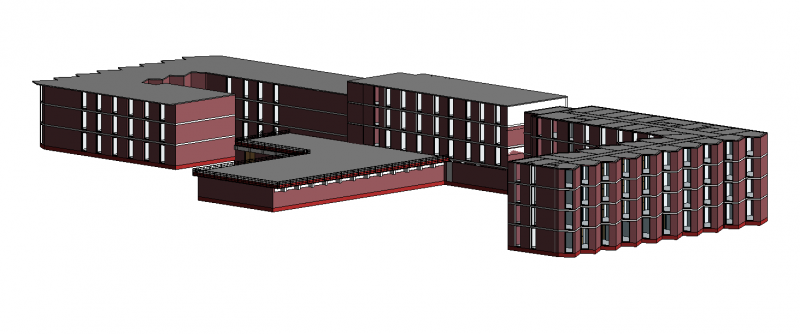

DECC recently completed a significant project on the UNSW campus, dismantling a former residential college block originally known as Baxter College, named in honour of Vice-Chancellor Sir Philip Baxter, and officially opened on 14 October 1966. The building later became known as UNSW Hall after Philip Baxter College moved to a newly constructed facility in 2014.

When UNSW determined that the structure had reached the end of its lifecycle, DECC undertook the meticulous task of systematically deconstructing the building.

Recovery and recycling of various elements of demolition waste is a crucial part of sustainable construction. DECC have been working on this since their beginnings, but working even smarter remains an important focus, which is why they entered into a partnership with the Digital Twin and Land Tenure Engineering Lab led by Associate Professor Mohsen Kalantari at UNSW’s Centre for Infrastructure, Engineering & Safety (CIES) on this campus project, to increase the environmental sustainability of their practise.

Mobilising onsite on campus in January 2023, DECC began with a comprehensive strip out of the buildings using both hand and mechanical methods to optimise material recovery and maximise recycling opportunities. In conjunction with the strip out phase, DECC proceeded with hazmat removal before beginning structural demolition of Block C. The process was executed using conventional demolition techniques in reverse construction order.

Subsequent demolition of Blocks B and A involved large excavators, ranging from 38t to 48t, equipped with hydraulic attachments such as hammers, pulverisers, and grapples. These machines methodically dismantled the remaining structures, prioritising safety, efficiency, and resource recovery.

‘We developed a sustainability tool for DECC,’ A/Prof Kalantari explains, ‘so they can calculate the CO2 emissions as a result of their demolition and recycling processes. Some materials like concrete, brick and metal can be recycled, and others, such as asbestos, mixed waste and soil, cannot. We developed the tool so they can calculate how much they have contributed to reducing CO2 emissions due to their recycling of material.

‘The tool also helps them to minimise their carbon footprint when taking non-recycled material to the waste centres. Additionally, we experimented with digital twinning technologies such as laser scanning and BIM to see if DECC could improve the accuracy of its estimations of the quantity of materials before demolition.’

By April 2023, DECC had successfully completed the demolition component of the project, safely processing the demolition waste and transporting materials to recycling facilities across Sydney, reflecting their commitment to sustainable deconstruction practices. From April onwards, DECC transitioned into the civil and landscaping phase with project completion achieved in December 2023.

Partnership brings great outcomes:

DECC Director Frank Lombardi says, ‘The partnership with UNSW has been a great step forward for DECC. The sustainability tool developed will enable us to measure recycling efforts and emission reduction across all future DECC projects. It will make a huge impact on how we approach and achieve our sustainability goals.’